Machine show :

If you're looking for efficiency in a CNC machine, our UC-481 are an excellent way to go. These machines allow you to increase the speed of production and improve the quality of your cuts, growing your business along the way. Excellent for making surf racks, shelf units, kitchen cabinets, skis and much more, our large CNC machines are designed to make setup and programming effortless, all while giving you highly precise edge finishes.

Machine Description:

| Model | UC-481 with ATC loading unloading |

| X-Y-Z axis working area | 1220 x 2440 x 200mm |

| Repositioning resolution | 0.02mm |

| X-Y movement | rack and pinion, gear drive/Taiwan |

| Z movement | ball screw drive/Germany |

| Max. speed | 45,000mm/min |

| Max. cutting speed | 35,000mm/min |

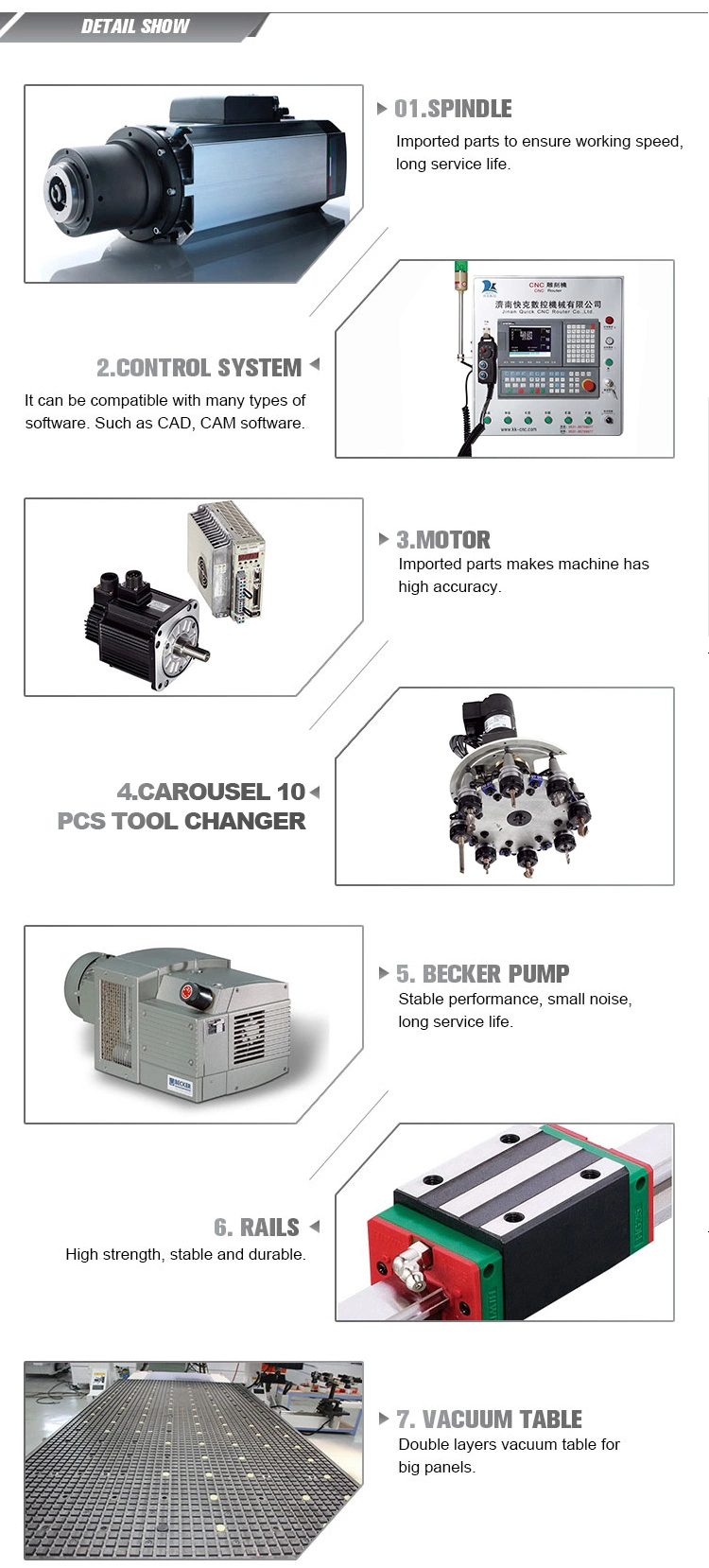

| Spindle power | 9.6kw Italy HSD air cooling |

| Spindle speed | 18,000rpm |

| Inverter power | 11kw |

| Drive motors | Servo Yaskawa |

| Working voltage | AC380V/50-60Hz,3-phase |

| Command code | G code |

| Table | Double layer vacuum table |

| Software | Type 3 |

| Controls | Syntec 6MB |

| Optional | 1.Dust collector 2.Germany Becker vacuum pum 3.rotary device 4.Mist cooling system 5.HSD boring Head |

Step 3 To achieve the work:

Step1: Loading. There is a lifting platform in front of the machine, which will raise the processing material. After the gantry moves to the target position, the suction cup after the gantry will lift the plate from the pulley through the bed to the fixed processing area

Step2: Processing. Material to the processing area, Position cylinder to fix material position, open the adsorber valve and start the processing

Step3: Unloading. After finishing the material processing, the push tube behind the gantry pushes the material to the unloadinging platform, saving the time of stopping the machine and removing the material

Samples:

Advantage:

1. The UC-481 machine is easy to operate, and the engraved products have high precision and quality.

2. Precision rack and pinion transmission. Tooth face is heat treated with features of high efficiency transmission, Bearing high torque, low noise.

3. The liner guide way has middle preloading design, features of high precision and stability may prolong liner guide way.

4. Ruggedly constructed machine structure. Material is Stress relieved and annealed for deformation free.Machine base's five sides are produced at one same procession. High accuracy machine.

5. Syntec Large storage space, perfect U disk compatibility, fast reading speed, safe and reliable U disk-processing. High anti-jamming intensity passes many CE tests.

Service:

1) Provide you with one year free warranty service

2) According to your needs, provide you with the best equipment procurement solution

3) Provide services to you through Whatsapp, WeChat, email, 24-hour phone

4) We will provide consumable parts at agency prices

5) We provide manuals and CDs (guidance videos) about machine software installation, operation and maintenance

6) Without involving hardware changes, a new version of the operating system will be provided to you free of charge

Product application:

1) Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

2) The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

3) Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

4) Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process

Company Information:

FAQ:

Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

Q: How does your factory do regarding quality control?

A: Quality is priority. Our leaders always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

Q: What's your warranty terms?

A: One year warranty for normal use and we supply maintanence for free.

Q: Will you deliver the right goods as ordered ? How can I trust you ?

A: Yes, we will. The core of our company culture is honesty and credit. We have been engaged in engraving machine industry for 15 years, and the trust of our customers is obvious to all.