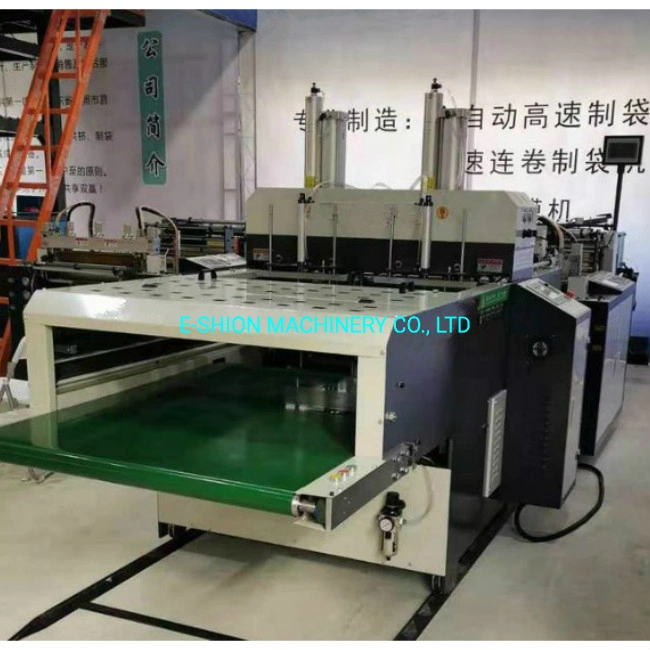

DFR-400x2C

Automatic Super High Speed Double Line Double-Color PLA

T-shirt Bag Making Machine

This machine is suitable for PLA Biodegradable material,high-density polyethylene (HDPE), low-density polyethylene (LDPE), tube natural color and printed plastic film materials for heat sealing and cutting bags.

CHARACTERISTICS OR MAIN TECHNICAL VARIABLES:

Performance and characteristics of automatic ultra-high speed bag making machine:

1. This machine is a special machine for heat sealing and cutting of vest bags, which can automatically punch two lines, increase output and save manpower.

2. This machine is double track, double production line, double printing bag, double servo motor.

3. Electric eye induction tracking, accurate printing pattern, automatic stop warning when electric eye fails.

4. Host motor inverter control, easy to operate and reduce power consumption.

5. Automatic stop device without material.

6. When the machine reaches the set number of sheets, the punching machine immediately clamps the bag without stopping the machine and can continue to feed.

7. The newly designed sealing knife structure, when the sealing knife needs to be cleaned, the sealing knife can be turned over 100 and fixed for cleaning, which is safe, reliable and easier to maintain.

8. The bag is tidy and the seal is firm.

9. Gas-liquid pressurized cylinder punching machine is adopted, with low noise and small air consumption.

The main technical parameters:

we also can make hot sealing cold cutting machine .

Model GFQ-1000 /GFQ-1200/GFQ-1400 and more bigger size machine could be special ordered.

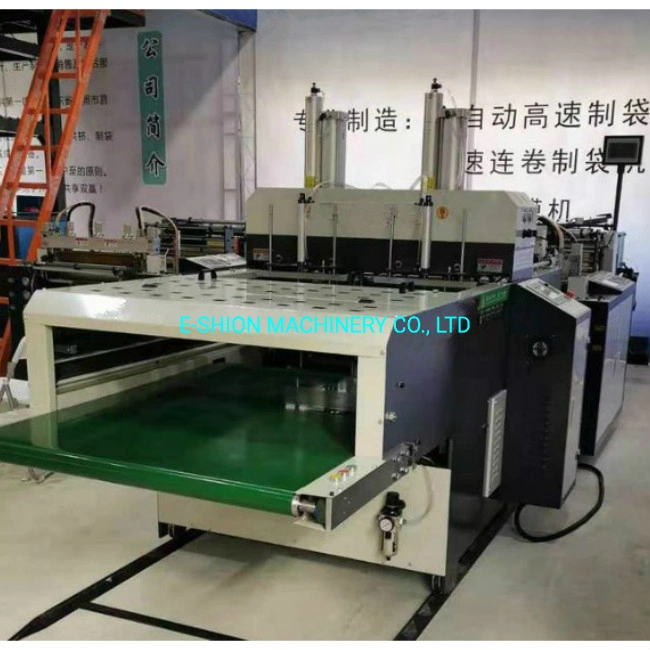

Automatic Super High Speed Double Line Double-Color PLA

T-shirt Bag Making Machine

This machine is suitable for PLA Biodegradable material,high-density polyethylene (HDPE), low-density polyethylene (LDPE), tube natural color and printed plastic film materials for heat sealing and cutting bags.

CHARACTERISTICS OR MAIN TECHNICAL VARIABLES:

Performance and characteristics of automatic ultra-high speed bag making machine:

1. This machine is a special machine for heat sealing and cutting of vest bags, which can automatically punch two lines, increase output and save manpower.

2. This machine is double track, double production line, double printing bag, double servo motor.

3. Electric eye induction tracking, accurate printing pattern, automatic stop warning when electric eye fails.

4. Host motor inverter control, easy to operate and reduce power consumption.

5. Automatic stop device without material.

6. When the machine reaches the set number of sheets, the punching machine immediately clamps the bag without stopping the machine and can continue to feed.

7. The newly designed sealing knife structure, when the sealing knife needs to be cleaned, the sealing knife can be turned over 100 and fixed for cleaning, which is safe, reliable and easier to maintain.

8. The bag is tidy and the seal is firm.

9. Gas-liquid pressurized cylinder punching machine is adopted, with low noise and small air consumption.

The main technical parameters:

| MODEL | DFR-400x2C | DFR-450x2C | DFR-500x2C |

| Max.width of bag | 360mmx2 | 410mmx2 | 450mmx2 |

| Bag length | 660mm | 680mm | 750mm |

| Speed | 140-300*2pcs/min | 140-300*2pcs/min | 140-300*2pcs/min |

| Film thickness | 0.008-0.035 | 0.008-0.035 | 0.008-0.035 |

| Main motor | 1.5kw | 1.5kw | 1.5kw |

| Total power | 10kw | 10kw | 10kw |

| Air compressor | 7kg/cm2; 700Ni/min | 7kg/cm2; 700Ni/min | 7kg/cm2; 700Ni/min |

| Feeding size | 800mm | 800mm | 800mm |

| Machine weight | 2300kg | 2300kg | 2300kg |

| Overall dimension | 7000x1600x1700mm | 7000x1700x1700mm | 7000x1700x1700mm |

we also can make hot sealing cold cutting machine .

Model GFQ-1000 /GFQ-1200/GFQ-1400 and more bigger size machine could be special ordered.