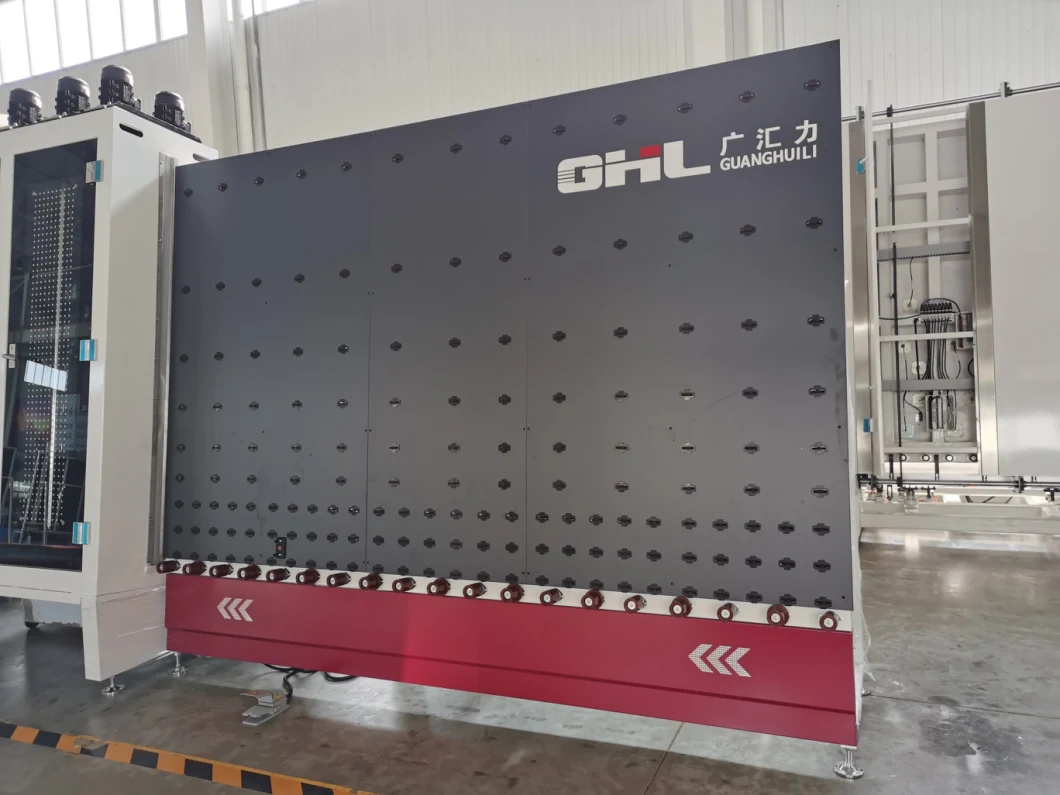

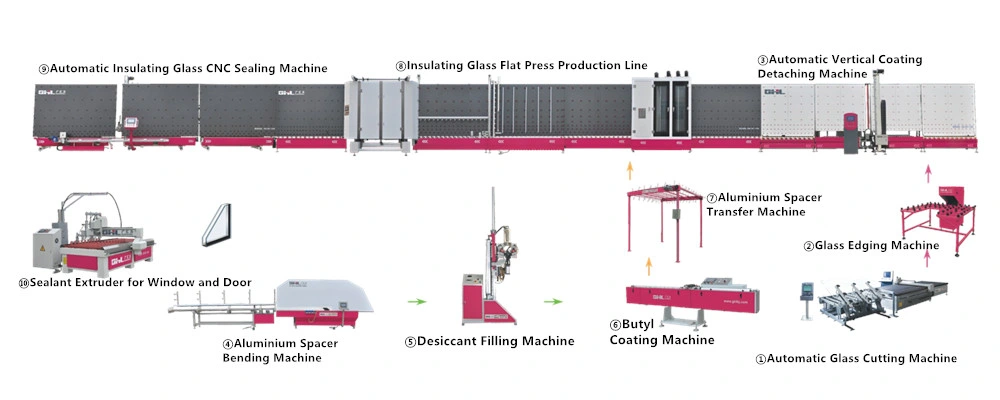

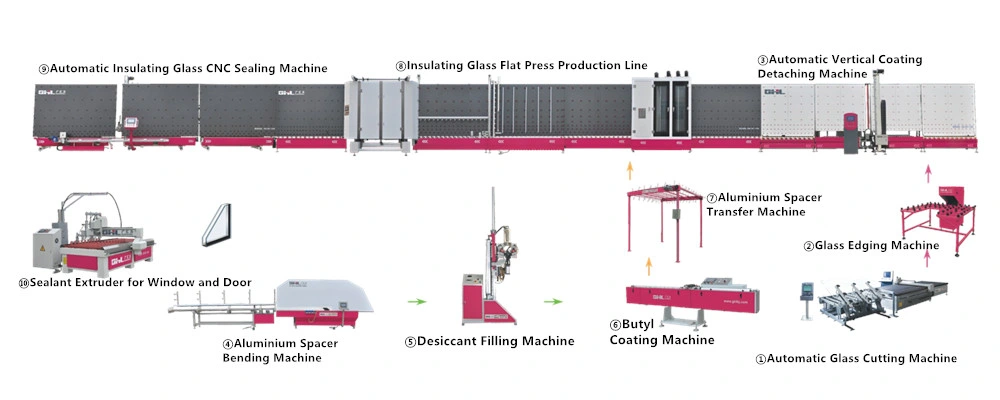

01 section:

MAIN COMPONENTS

- Automatic recognition LOW-E glass and coated glass, automatic warning if the glass is reversed.

- Each brush drived with one electric motor separately, high density brush,wash clean.

- The bearings equipped with three seals including two oil seals and a waterproof so that can avoid water and dust into the bearings

- Universal water spray nozzle, clean glass completely.

- Special octopus air knife, blowing wind with three sections parallelly, ensure the effect of drying glass. There is a dam-board nearby the air knife, ensure the wind even and powerful. Equipped with stainless steel chain.

- Mechanical identification glass thickness, keep the best distance between air knife and glass.

- Large fan power. Equipped with sound-absorbing cotton in the fan crate, reduce the noise pollution.

- Tuyere close automatically when there is glass , avoid waterlogging.

- The water tank is gradient, outfall at bottom, cleaning sediment completely.

- The hosepipe connect motor and machine has drop, avoid freeze in winter.

- This section with speed up sensor, transporting quickly and improving efficiency.

- Hand-operated positioning, easy to adjust, accurate positioning. The censor can perception the height of glass in advance to make the beam on the fifth section come down ahead, save time, improve efficiency.

- Adopt lengthen block bearing and trepanning at relevant position , avoid small glass drop down. Position triple glass accurately .

- The pressing section adopts long stroke length, convenient to maintenance. The stiffener distributed evenly,small interval, avoid horn mouth and breaking glass when pressing .

- This part adopts hydraulic transmission, stable and efficient.

- All chains with protective cover, safety

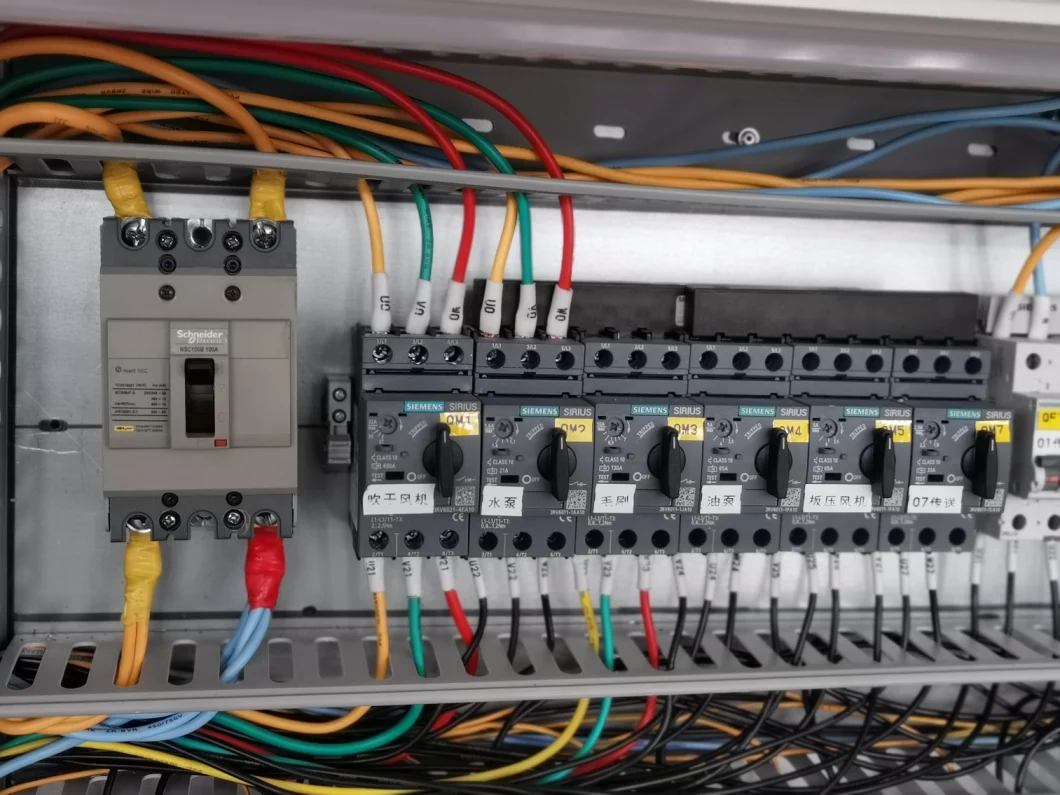

- PLC and 7 sets frequency converter adopt Germany Siemens.

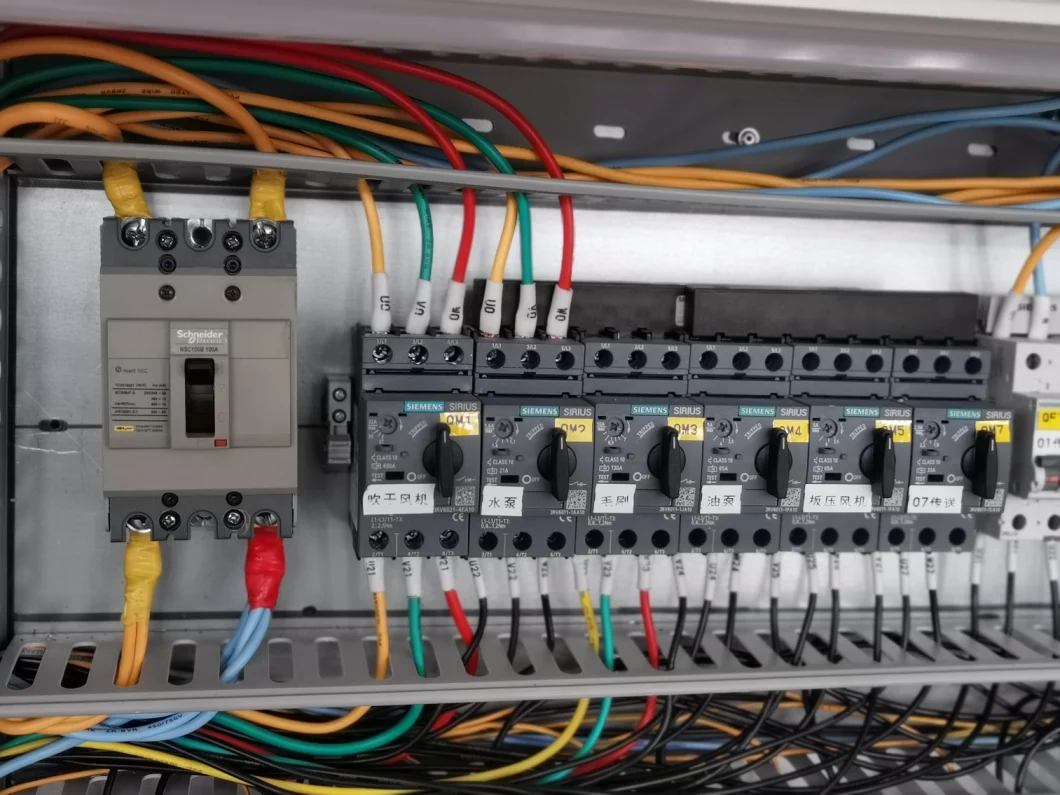

- Low voltage electrical apparatus adopt Germany Siemens ,relays adopt France Schneider

- Adopt aviation plug, safe and convenient, reduce labor cost.

- Ethernet transmission, fast speed, high precision

| Model | LBJ2025 | LBJ2030 | LBJ2536 |

| Input Voltage | 380V 50HZ | 380v 50Hz | 380v 50Hz |

| Total Power | 30 KW | 30 KW | 34 kw |

| Max. Glass Size | 2000*2500mm | 2000*3000mm | 2500×3500mm |

| Min.Glass Size | 300*500mm | 300*500mm | 450×280mm |

| Washing glass thickness | 3-12mm | 3-12mm | 3-12mm |

| Working speed | 8~45m/min | 8~45m/min | 8-45m/min |

| Overall dimension | 19000*1800*3100mm | 22000*1800*3100mm | 26000×1800×3600mm |

| Total weight | 5500 kg | 6000 kg | 7000 kg |

| Name | Brand | Place of origin |

| Programmable PLC | SIEMENS | GERMANY |

| Frequency converter | SIEMENS | GERMANY |

| Touch Screen | KINCO | CHINA |

| Relays | SCHNEIDER | FRANCE |

| Buttons | SCHNEIDER | FRANCE |

| Light | SCHNEIDER | FRANCE |

| Proximity switch | OMRON | JAPAN |

| Motor | MAILI | CHINA |

| Photoelectric switch | Autonics | KOREA |

| Pneumatic components | AIRTAC | TAIWAN |

| Washing system | GHL | CHINA |

| Transport system | GHL | CHINA |

| Pressing system | GHL | CHINA |

| Hydraulic station | GHL | CHINA |