Technical features:

1.Strong welded construction with high quality coating paint.

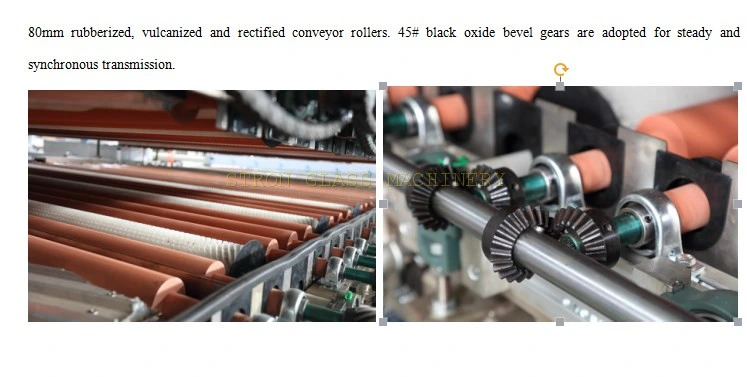

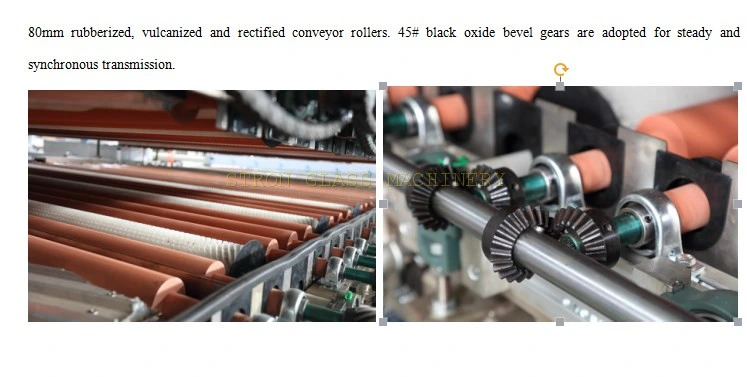

2.80MM rubberized vulcanized and rectified conveyor rollers.

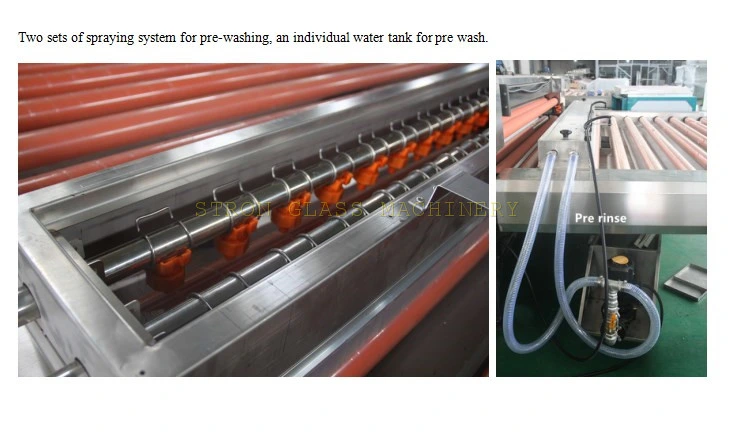

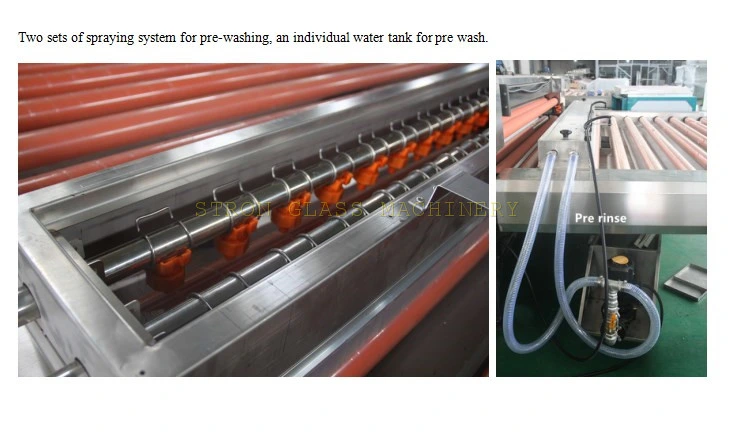

3.Loading section equipped with stainless steel water tank and high pressure spraying system for pre-washing. All stainless steel components and tanks for all water applications. Loading table rollers are dipped in water for better cleaning of the glass. This can avoid scratches on glass or rollers.

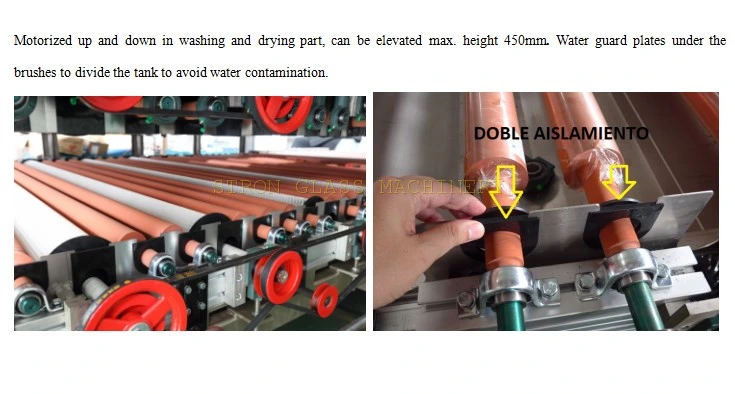

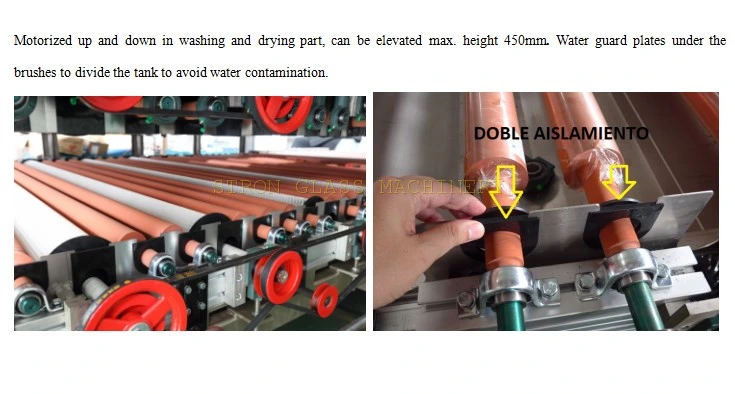

4.Washing and drying sections can be lifted to 450mm automatically for cleaning and maintenance. Hard and strong screws are used in this part.

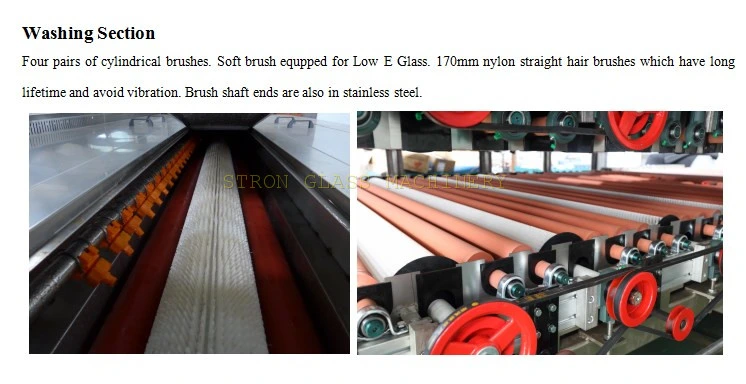

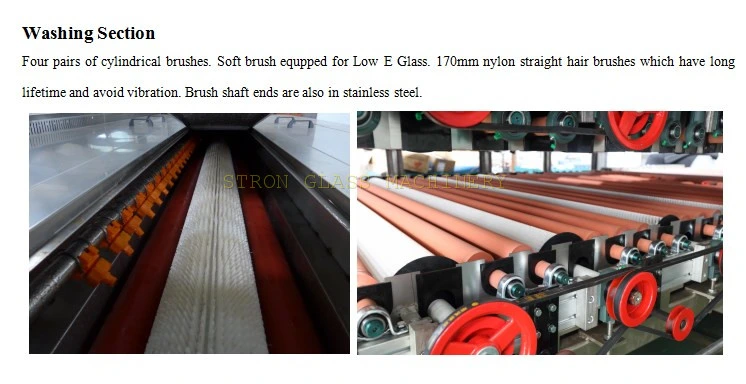

5.There are 2 pairs of brushes, brush shaft diameter is 170mm and shaft end are made by stainless steel. Brush for Low-E glass washing.

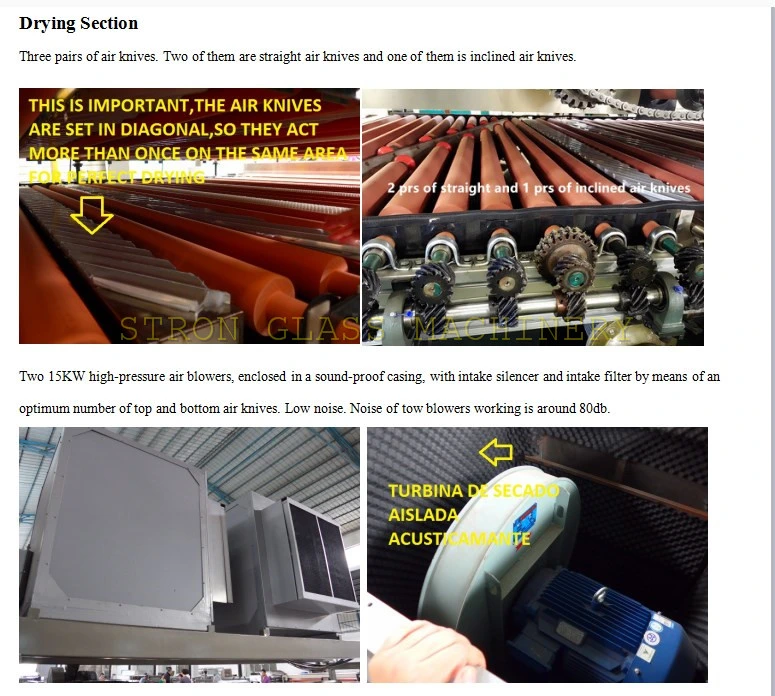

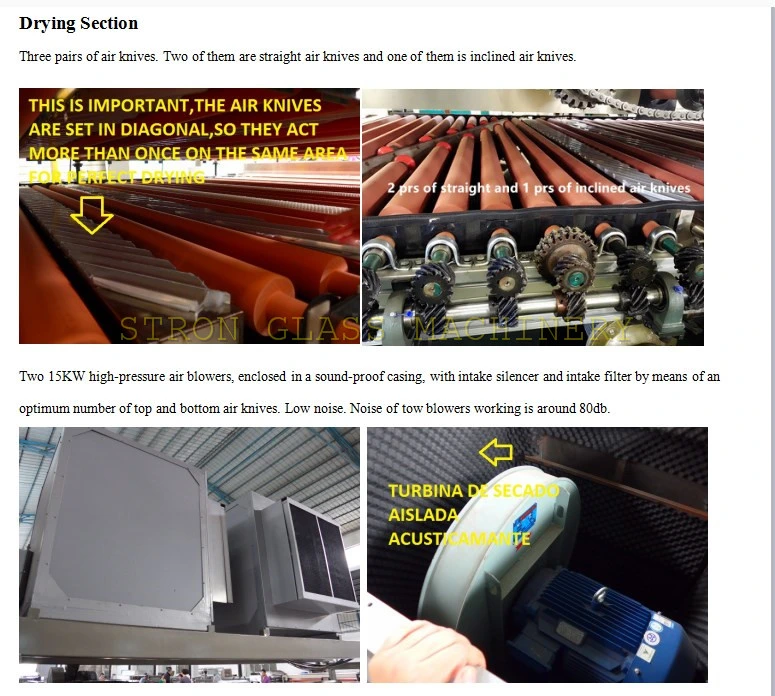

6.The inclined blower ensures perfect drying. Two sets air knives are adjustable up and down. Blower packed with muffle cotton can largely minimize the noise. There's a platform and guard rails near the blower box for easy daily maintaince.

7.Multi-stage drying system, air knives is made by stainless steel that enable washing efficiency is higher than traditional air knives. Wind transferred in sets of bellows, less wind will be lost and noise can be lowered compare with traditional structure. Glass will be dried with natural wind, drying efficiency will be improved obviously. This also lengthens the drying function of the machine.

8. Conveyor device: Bevel gear is adopted for steady and synchronous transmission.

9.Economical water circulation systems, a quick connector between the water tank and pump which can take down when cleaning.

10. Motors, blower, pump, transmission, lighting, up/down can be controlled by electric panel. Frequency speed control, with digital display for speed, glass thickness and up/down distance.

Specification

MACHINE DETAILS:

EXHIBITIONS:

1.Strong welded construction with high quality coating paint.

2.80MM rubberized vulcanized and rectified conveyor rollers.

3.Loading section equipped with stainless steel water tank and high pressure spraying system for pre-washing. All stainless steel components and tanks for all water applications. Loading table rollers are dipped in water for better cleaning of the glass. This can avoid scratches on glass or rollers.

4.Washing and drying sections can be lifted to 450mm automatically for cleaning and maintenance. Hard and strong screws are used in this part.

5.There are 2 pairs of brushes, brush shaft diameter is 170mm and shaft end are made by stainless steel. Brush for Low-E glass washing.

6.The inclined blower ensures perfect drying. Two sets air knives are adjustable up and down. Blower packed with muffle cotton can largely minimize the noise. There's a platform and guard rails near the blower box for easy daily maintaince.

7.Multi-stage drying system, air knives is made by stainless steel that enable washing efficiency is higher than traditional air knives. Wind transferred in sets of bellows, less wind will be lost and noise can be lowered compare with traditional structure. Glass will be dried with natural wind, drying efficiency will be improved obviously. This also lengthens the drying function of the machine.

8. Conveyor device: Bevel gear is adopted for steady and synchronous transmission.

9.Economical water circulation systems, a quick connector between the water tank and pump which can take down when cleaning.

10. Motors, blower, pump, transmission, lighting, up/down can be controlled by electric panel. Frequency speed control, with digital display for speed, glass thickness and up/down distance.

Specification

| Max. Glass Size | 2500 | MM |

| Min. Glass Size | 400*400 | MM |

| Glass Thickness | 3~25 | MM |

| Working Speed | 0.6~16 | M/MIN |

| Blower Power | 15KW*2 | set |

| Total Power | 52 | KW |

| Brush | 3 | pair |

| Brush Shaft Diameter | 170 | MM |

| Roller Diameter | 80 | MM |

| Water Tank | 3 | unit |

| Air Knives | 2 | Pair |

| Table Height | 900±50 | MM |

| Net Weight | 5000 | KG |

MACHINE DETAILS:

EXHIBITIONS: