Application

Model ST02 sealant spreading machine is made with the latest domestic and international technologies, which applies to the sealing and spreading of secondary sealant. A /B pump adopt S. Korea pneumatic air motor, which works sensibly and reliably. Its unique adjustable proportioning mechanism meets the rigorous requirements for double constituent sealant proportion to maximum extent, with a smooth sealant flow, good coating effect and high production efficiency as well.

Feature

- Suitable for mass production of insulating glass and curtain wall

- Pneumatic control, easy for operation

- A/B air motor adopt American advanced technology, S. Korea brand air motor

- Integrated structure of A/B sealant pump, avoid sealant leakage

- Special device to avoid A/B sealant pump running idle.

- Special one-way value in high pressure pump, sealant output smoothly, suitable for all kinds of sealant, avoid incomplete mixing.

- Multi filter system to keep clean of sealant

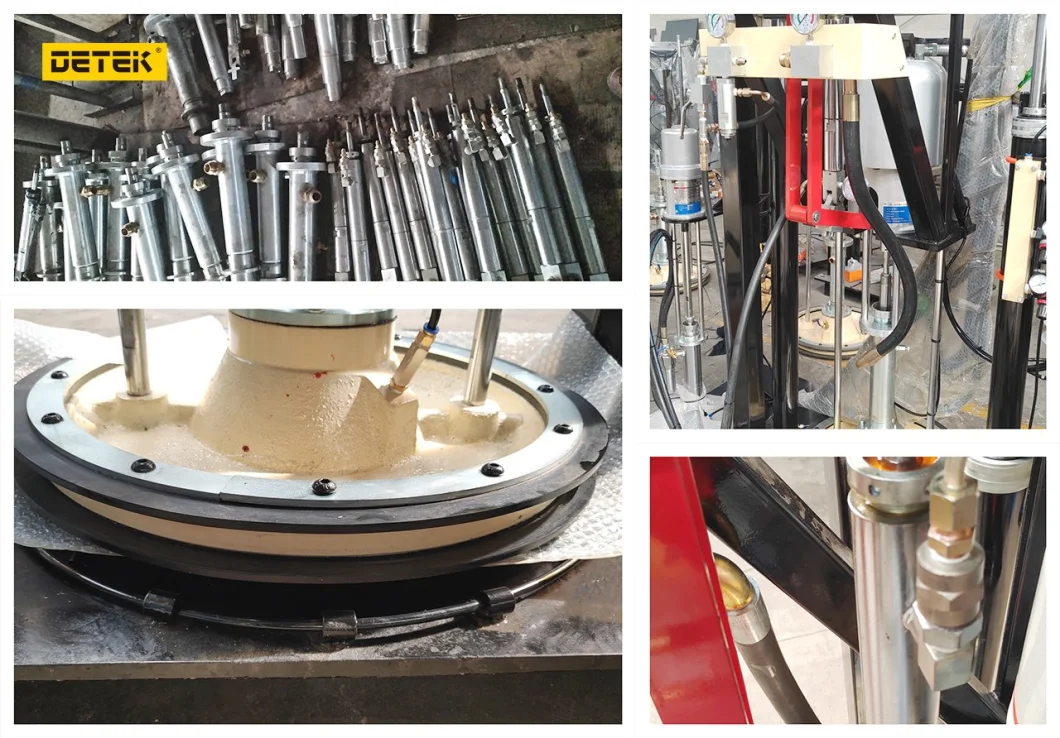

- Stainless steel mixer and unique sealing gun, guarantee the sealant mixing effect

- One-way valve is made of high wear-resistant material, long life time

- The rotating arm is equipped with universal device, flexible and portable

| Mixing ratio | 6:1-14:1 |

| Sealant output | 4-10L/min |

| Max. dispensing pressure | 30Mpa |

| Air supply | 0.8-1.0 Mpa |

| Air consumption | 0.8M3/min |

| Diameter of A/B drum | 570mm/280mm |

| Dimension | 1750×950×1980mm |

| Weight | 510Kg |

Brand parts list

| Name | Brand | Country |

| A/B air motor | Hasco/YL | S. Korea |

| Safety valve | Hasco | S.Korea |

| Pressure gauage | Delta | TAIWAN |

| Sealing gun | Self-made | China |

Mostly asked questions below:

1. What is your soonest lead time?

A: 60 days for whole production line, 30 days for single machine. Special requirement pls check with sales.

2. How do you arrange the shipment?

A: all machines fit GP for sea freight saving. Seaworthy package, workshop container loading, safe arriving.

3. Guarantee ?

A: One-year guarantee (wearing parts are out of this range). Life long service. DETEK will send engineers for service upon request onsite.

4. How we can install the machines?

A: Installation included; however, customers need to pay our engineer's round way air tickets, local transportation and accommodation (hotel and food).

The installation should be finished within 15 days, and will be charged 60USD/engineer/day.

5. How about the after service?

A: Spare parts within 72 hours.

Experienced technical sales sort out most of your questions.

Tens of service engineers ready for on-site service and instruction.