1. Introduction:

Insulating glass production line is a kind of glass deep processing equipment, which is mainly used to process and produce insulating glass. The original glass is cut into the hollow production line

The main processing procedure as follows: cleaning, drying, installing the spacer frame with butyl, assembly the glass. After assembly work, operator should make the second sealing (polysulfide or silicone glue) and then unload the insulating glass.

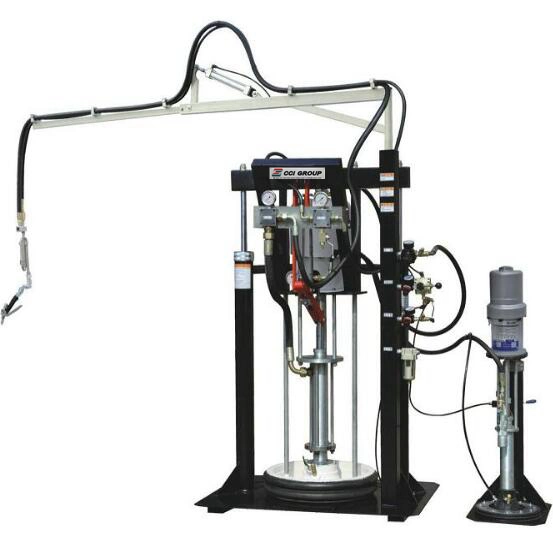

The silicone sealant coating machine is the necessary machine for achieving second sealing work.

It is widely used to mix rubbers evenly according to specific mixture ratio and spreading the mixed silicone sealant at fast speed.

The machine is pneumatic controlled and equipped with special spray gun, therefore it is most suitable for producing large areas of curtain wall insulating glass.

Adopts Korea HASCO pump, which can ensure the coating work steady and high effective.

Besides, We support the single component silicone sealant coating machine also.

Coating effects as follows:

Adopts Korea HASCO pump, which can ensure the coating work steady and high effective.

Besides, We support the single component silicone sealant coating machine also.

Coating effects as follows:

3. Installation Conditions:

3.1 Solid concrete floor.

3.2 Industrial tap water source and drainage ditch.

3.3 Clean and dust-free.

Pneumatic Components:

a.HASCO pneumatic parts;

b. Famouns brand pneumatic tube.

a.HASCO pneumatic parts;

b. Famouns brand pneumatic tube.

Stainless Steel Mixing Bar:

a. High-quality stainless steel mixing bar.

a. High-quality stainless steel mixing bar.

Mixing System Compoents:

a. Professional Spray Gun;

b. Four times silicone sealant mixing work;

c. 360 degree rotation function..

a. Professional Spray Gun;

b. Four times silicone sealant mixing work;

c. 360 degree rotation function..

Professional Squeezing Noozle

a. Standard size: 6mm/ 9mm/ 12mm;

b. If need special size, we can customize it for you.

a. Standard size: 6mm/ 9mm/ 12mm;

b. If need special size, we can customize it for you.

5. CCI GROUP Factory

CCIGROUP is headquartered in Jinan City, China. It is a world-renowned laser equipment company and a high tech enterprises integrating R&D, production and sales.

We are adhering to the tenet of "Quality first, customer first" and continues to grow. Main products include upvc window machine, aluminium window machine, insulating glass machine, fiber laser cutting machine, plasma cutting machine, laser marking machine, laser engraving machine, laser welding machine and laser cleaning machine and etc.

Our company has passed ISO and CE international quality management system certificates, and has obtained FDA certification for the US market. We have our independent export rights.Machines are exported to more than 50 countries and regions.

Wish cooperating with you to create a better future!

6. CCI GROUP Certificate

7. CCI GROUP Quality Control System

8. Exporting Package and Delivery

9. Client Care

To be continued..