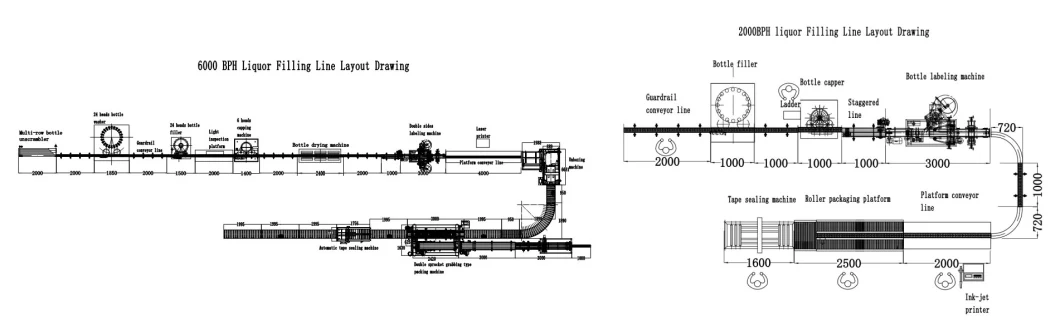

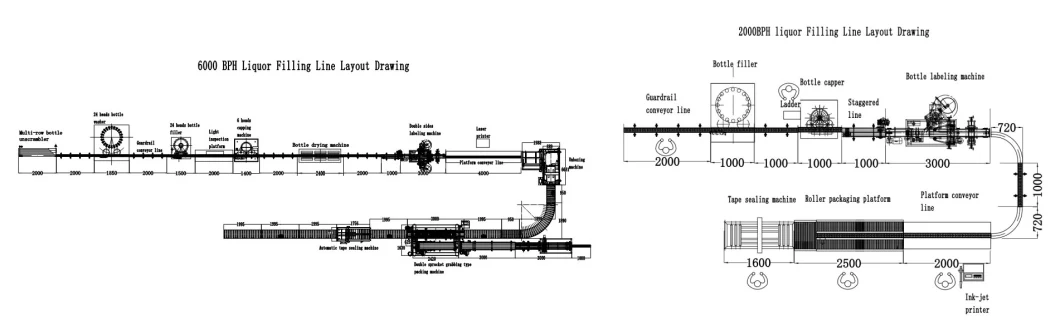

Automatic filling line layout drawing example

For a whole filling line we need to know:

1. Bottle dimension and bottle material

2. Cap dimension and cap type

3. Liquid kind

4. Production capacity

5. Label dimension

6. Packing type and packing material

7. Workshop sizeWhat we provide is customized equipment, different bottle shapes and sizes, as well as the production line output, the specific details of the equipment requirements, including the selection of stainless steel, the thickness of stainless steel, the selection of electrical accessories, we can all be customized.

For a whole filling line we need to know:

1. Bottle dimension and bottle material

2. Cap dimension and cap type

3. Liquid kind

4. Production capacity

5. Label dimension

6. Packing type and packing material

7. Workshop sizeWhat we provide is customized equipment, different bottle shapes and sizes, as well as the production line output, the specific details of the equipment requirements, including the selection of stainless steel, the thickness of stainless steel, the selection of electrical accessories, we can all be customized.

Introduction to filling line machine

Washing partFor wine, vodka, whiskey, milk and beverages in glass bottles, a bottle washer is required. If it is juice and alcohol in hard plastic bottles, there is no need for bottle washing machine.

Filling part

This filling machine is suitable for the vacuum filling of non-gas liquids such as wine, whiskey, rum, milk, beverages, etc. It is suitable for filling round, square, flat and special-shaped glass bottles and hard plastic bottles. Size and output can be customized.

This filling machine is suitable for the vacuum filling of non-gas liquids such as wine, whiskey, rum, milk, beverages, etc. It is suitable for filling round, square, flat and special-shaped glass bottles and hard plastic bottles. Size and output can be customized.

Capping partAccording to different types of caps, different capping machines are required, whether it is aluminum cap or plastic cap, we have corresponding capping machines. If the cap type is wooden stopper, we have a corking machine and a T-type corking machine, as well as a PVC capsule shrinker and aluminum foil grinder machine. At the same time we have two kinds of cap lifters to adapt to different cap types and output.

Sterilizing drying and labeling partFrom left to right, there are sterilization machine, bottle blow dryer(before labeling machine, in order to keep bottle dry), heat shrink label machine, sticker (paste) labeling machine.The sterilization machine is suitable for the filling line of milk and beverage, the blow dryer is suitable for the glass bottles that have passed the bottle washer or sterilizing machine (if it is a plastic bottle, the bottle washer is not required, and the blow dryer is not required), the heat shrink label machine, self-adhesive (paste) labeling machine is selected according to customer needs.

Carton packing part

From left to right are carton unpacking machine, carton packing machine, tape sealing machine, suitable for large-output packaging.

Bottle samples

Our this type filling line is suitable for filling non-gas, non-sticky liquids such as wine, whiskey, rum, juice, milk, etc.

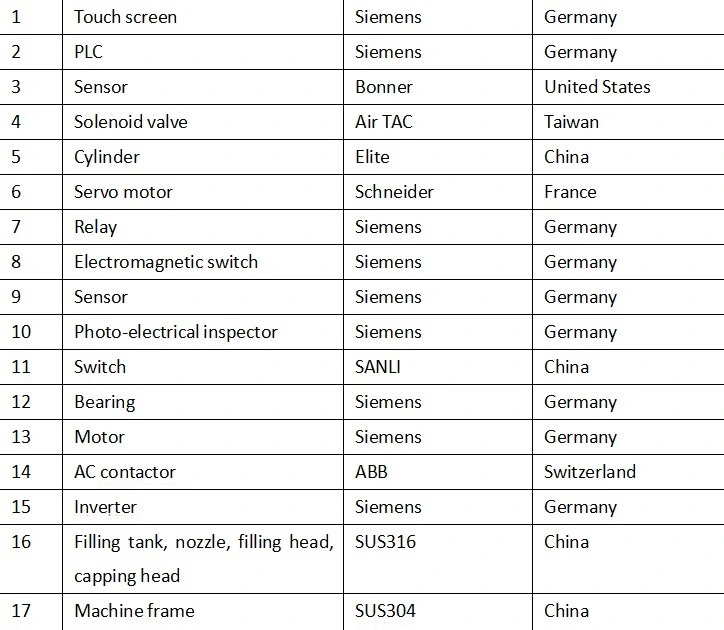

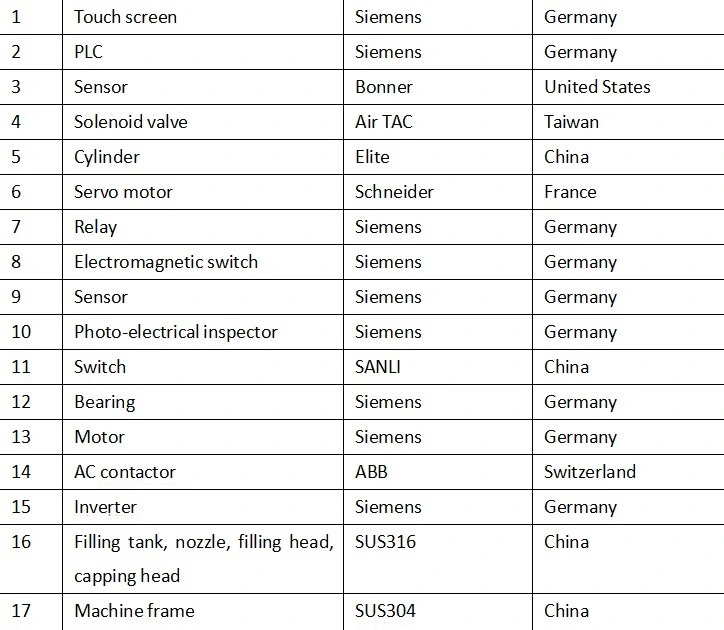

Main configuration

Certifications

Customer Photos

About us

We are a professional manufacturer of non-carbonated liquid bottling line equipment, we have more than 15 years' manufacturer experience in this field. We mainly manufacture non-carbonated liquid bottling line, our bottling equipment are mainly used for white spirit, grape wine, fruit wine, vinegar, soy sauce, cooking oil, enzyme, juice, non-carbonated drink, honey, syrup, tomato sauce, fruit jam, engine oil, lubricating oil...our bottling equipment mainly include bottle loading table, bottle washing machine, bottle filling machine, bottle capping machine, bottle sterilization machine, bottle drying machine, bottle labeling machine, inkjet printer, laser coder, tape carton sealing machine...

FAQ

Q1. Are you a manufacturer or trading company?

*We are a manufacturer with trading company who is registered in the Chinese Business Administration and has the right to operate and sell it legally.

*Tongda cooperates with Alibaba who will supply you a lot of service to protect you .

*Tongda has a professional engineer team who all have more than 15 years experience in filling machine manufacturing .

Q2. How to visit our factory?

*If you are interested in our products, you may visit our factory at any time , we can pick you up from the station or the airport near our city .

*Seeing is believing , you can see our machine quality after your visit.

Q3. How to ensure the machine quality?

*In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

*Each component before assembly needs strictly control by inspecting personnel.

*Before shipping, the whole machine will run more than 12 hours to ensure the stable running in your factory

Q4. How to guarantee your funds?

*We go through Alibaba.com Guarantee Service, which can protect your funds to be safe.

*We will send you pictures of the machine every week to ensure the delivery.

Q5. Machine after-sale service

*We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly.

*When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

*We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

*We provide 1 year warranty with spare parts free and life-long technical support.

*We are a manufacturer with trading company who is registered in the Chinese Business Administration and has the right to operate and sell it legally.

*Tongda cooperates with Alibaba who will supply you a lot of service to protect you .

*Tongda has a professional engineer team who all have more than 15 years experience in filling machine manufacturing .

Q2. How to visit our factory?

*If you are interested in our products, you may visit our factory at any time , we can pick you up from the station or the airport near our city .

*Seeing is believing , you can see our machine quality after your visit.

Q3. How to ensure the machine quality?

*In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

*Each component before assembly needs strictly control by inspecting personnel.

*Before shipping, the whole machine will run more than 12 hours to ensure the stable running in your factory

Q4. How to guarantee your funds?

*We go through Alibaba.com Guarantee Service, which can protect your funds to be safe.

*We will send you pictures of the machine every week to ensure the delivery.

Q5. Machine after-sale service

*We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly.

*When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

*We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

*We provide 1 year warranty with spare parts free and life-long technical support.